Graphene nanotubes for ESD floors: standards compliance & flexibility in color and thickness

Industrial floors in high technology sectors, the pharmaceutical and automotive industries, and cleanrooms require anti-static characteristics. Graphene nanotubes provide flooring unmatched performance by granting permanent, homogenous electrical conductivity without hot insulative spots and visual black dots, remaining stable regardless of humidity and allowing the flooring to pass the walking body voltage test. The extremely low dosage of easy-to-use graphene nanotube concentrates makes it possible to maintain the original mechanical abrasion resistance, impact resistance, and chemical resistance of the resin.

Main properties

Stable resistance

without “hot insulative

spots 10⁴–10⁹ Ω”

Clear, colorful surface

without black dots

Flexibility in floor

thickness

Standard processing

and equipment

ESD flooring with graphene nanotubes for enhanced safety

How does anti-static flooring work?

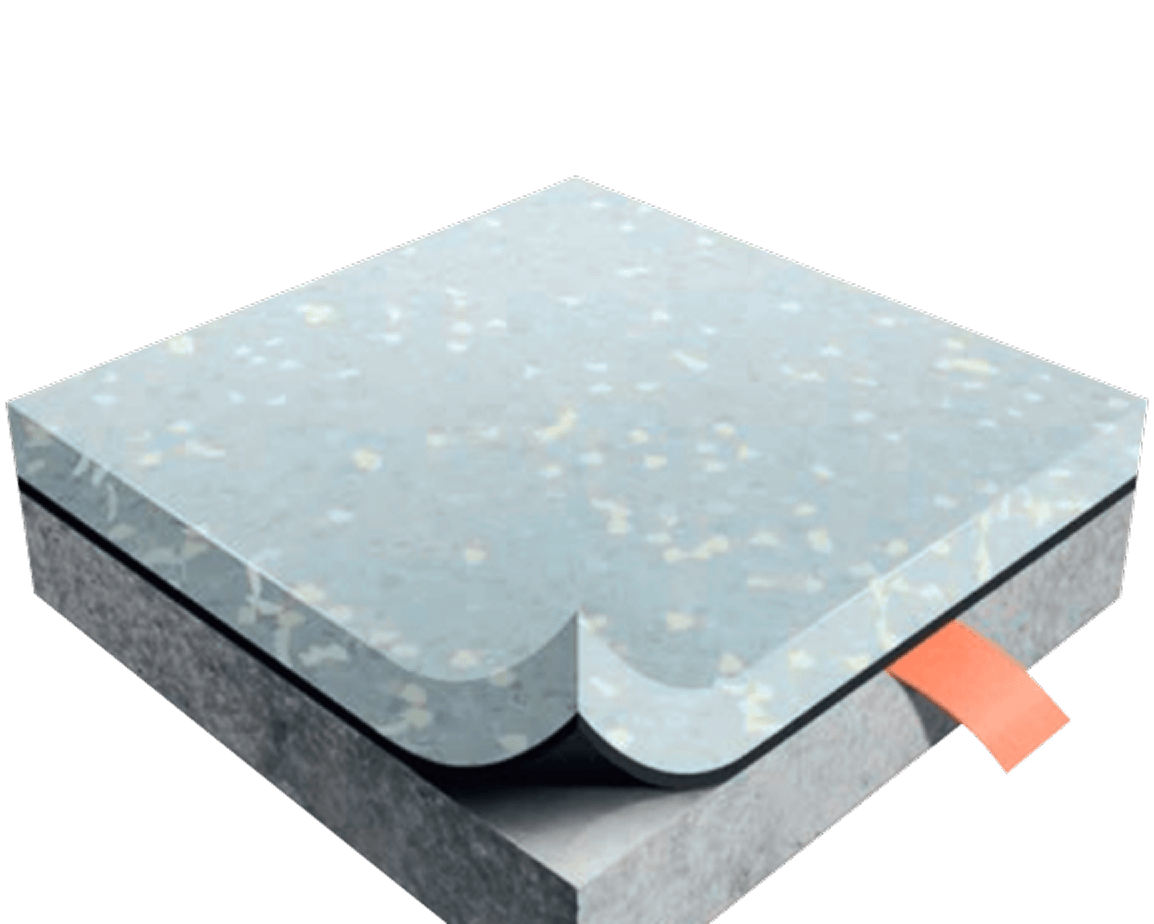

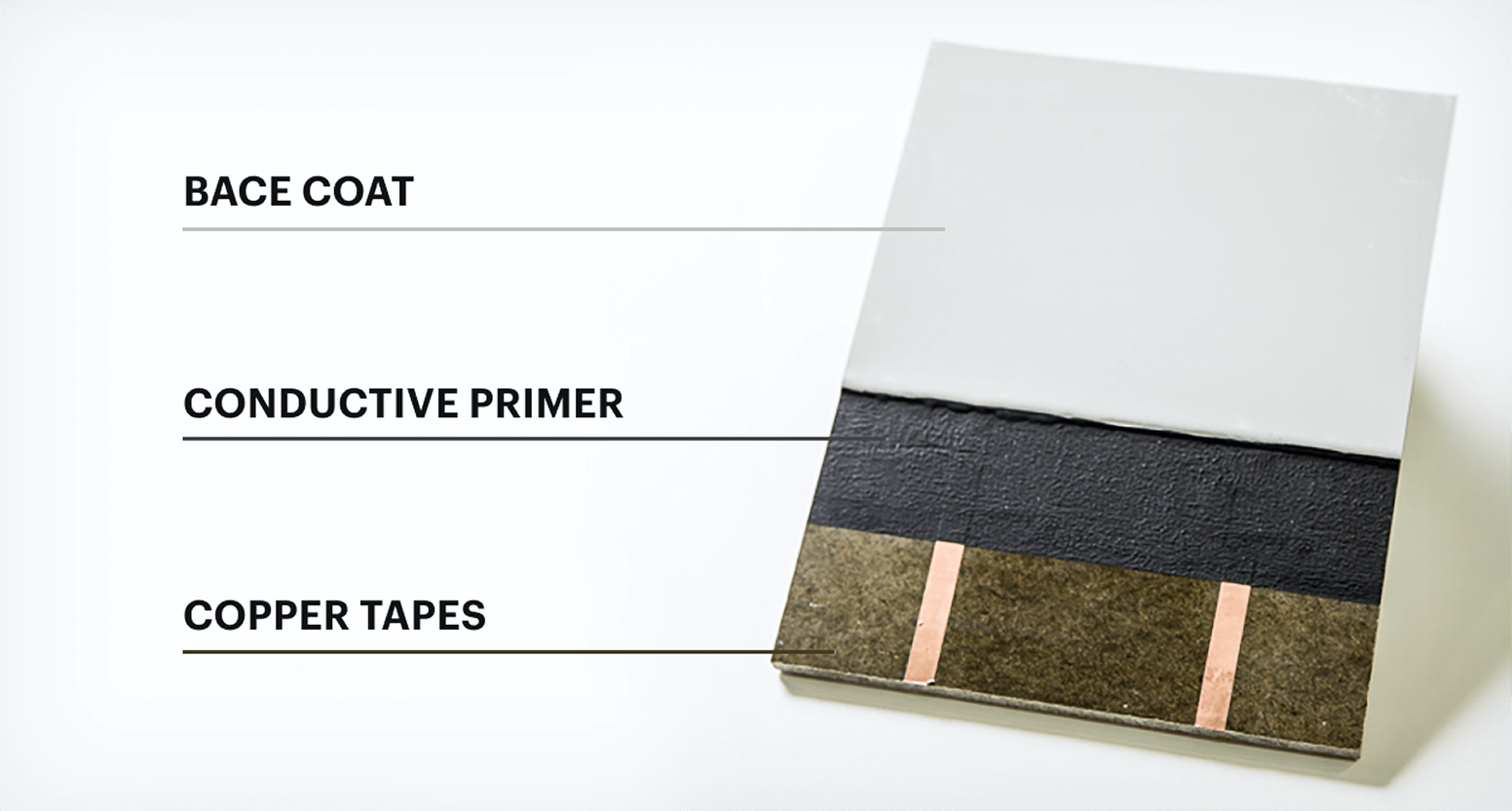

An ESD conductive flooring system can be comprised of layers such as copper tape, conductive primer, a base coat, and a thin topcoat. To conduct electrical charge from the surface to the ground, the originally insulative base coat should be made conductive. Self-leveling ESD floors must meet surface-to-surface or surface-to-ground resistance requirements, complying with IEC 61340-4-1, ASTM F150-06, and ANSI / ESD S20.20 standards.

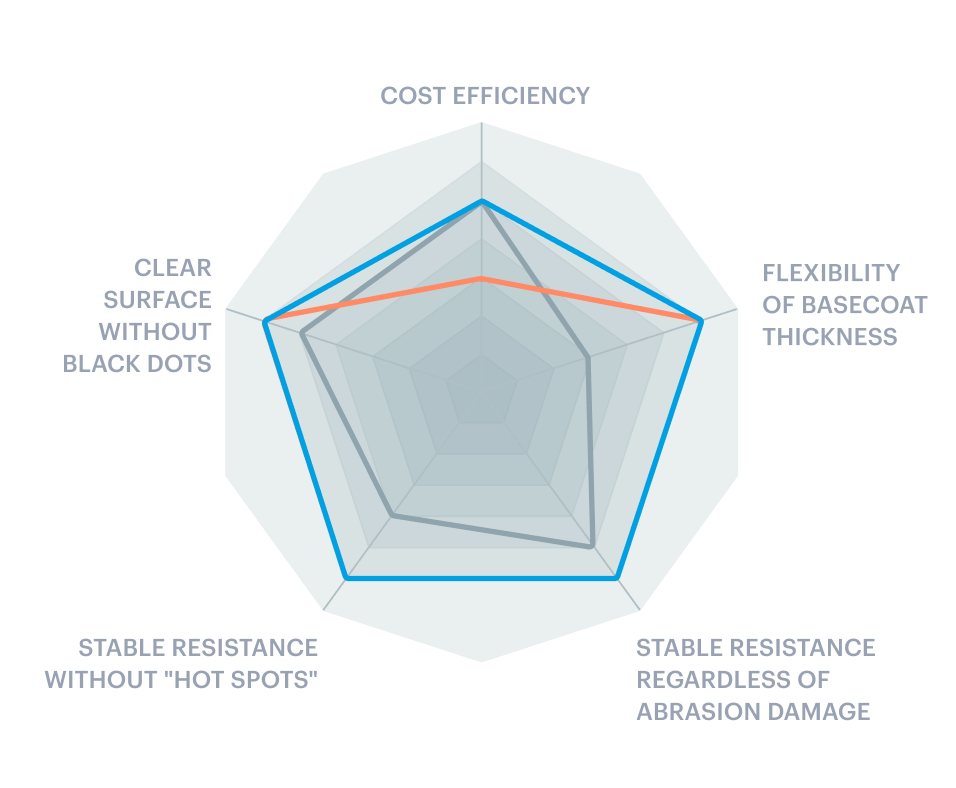

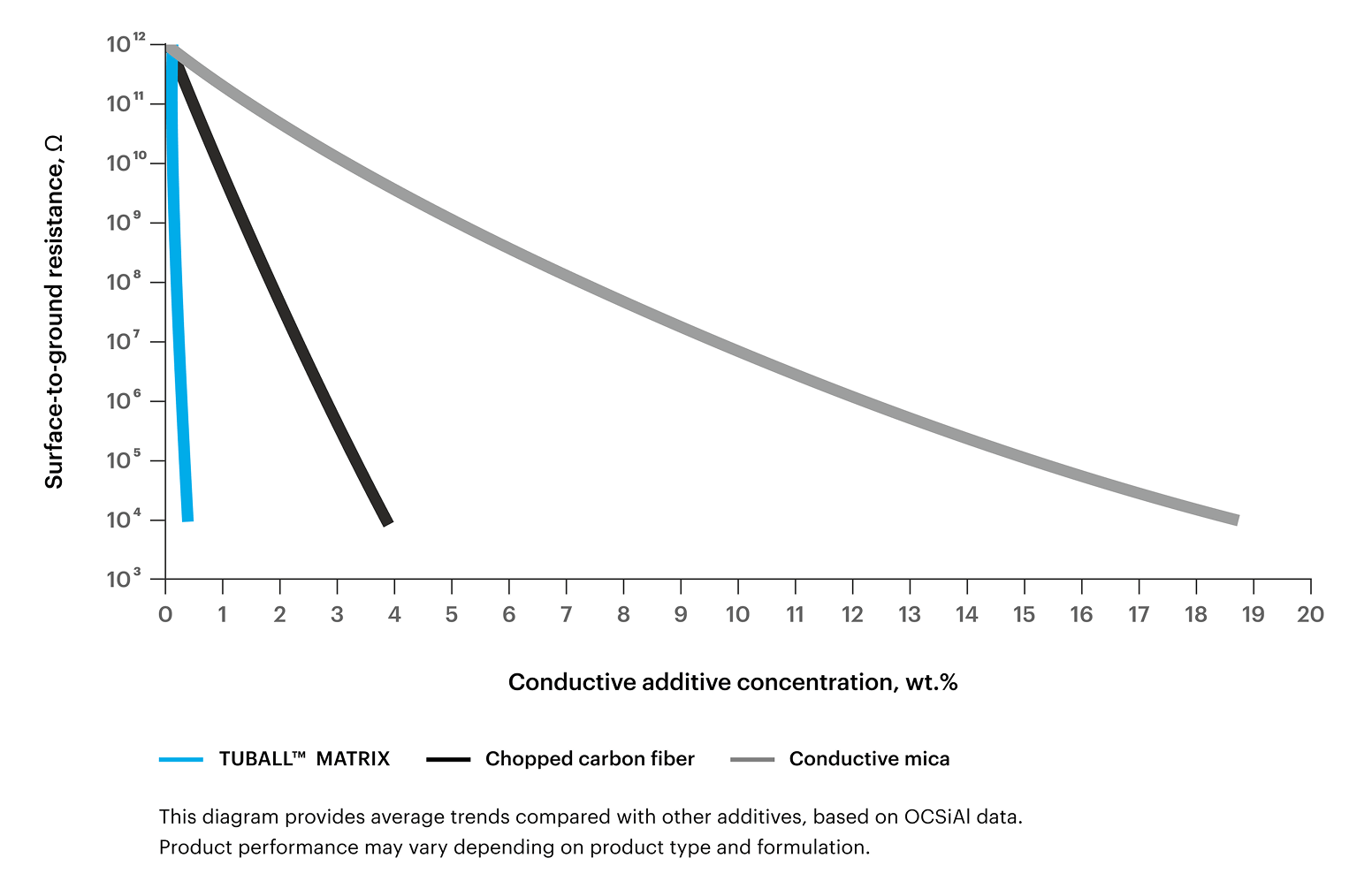

Nanotubes outperform standard additives for electrostatic discharge floors

Ultra-strong, ultra-long, electrically conductive and flexible, graphene nanotubes create a 3D conductive network inside the material at extremely low working dosages. This allows them to be a versatile conductive agent offering strong performance on all key parameters.

- DIAGRAM

- TABLE

- TUBALL™

- Conductive pigments

- Chopped carbon fibers

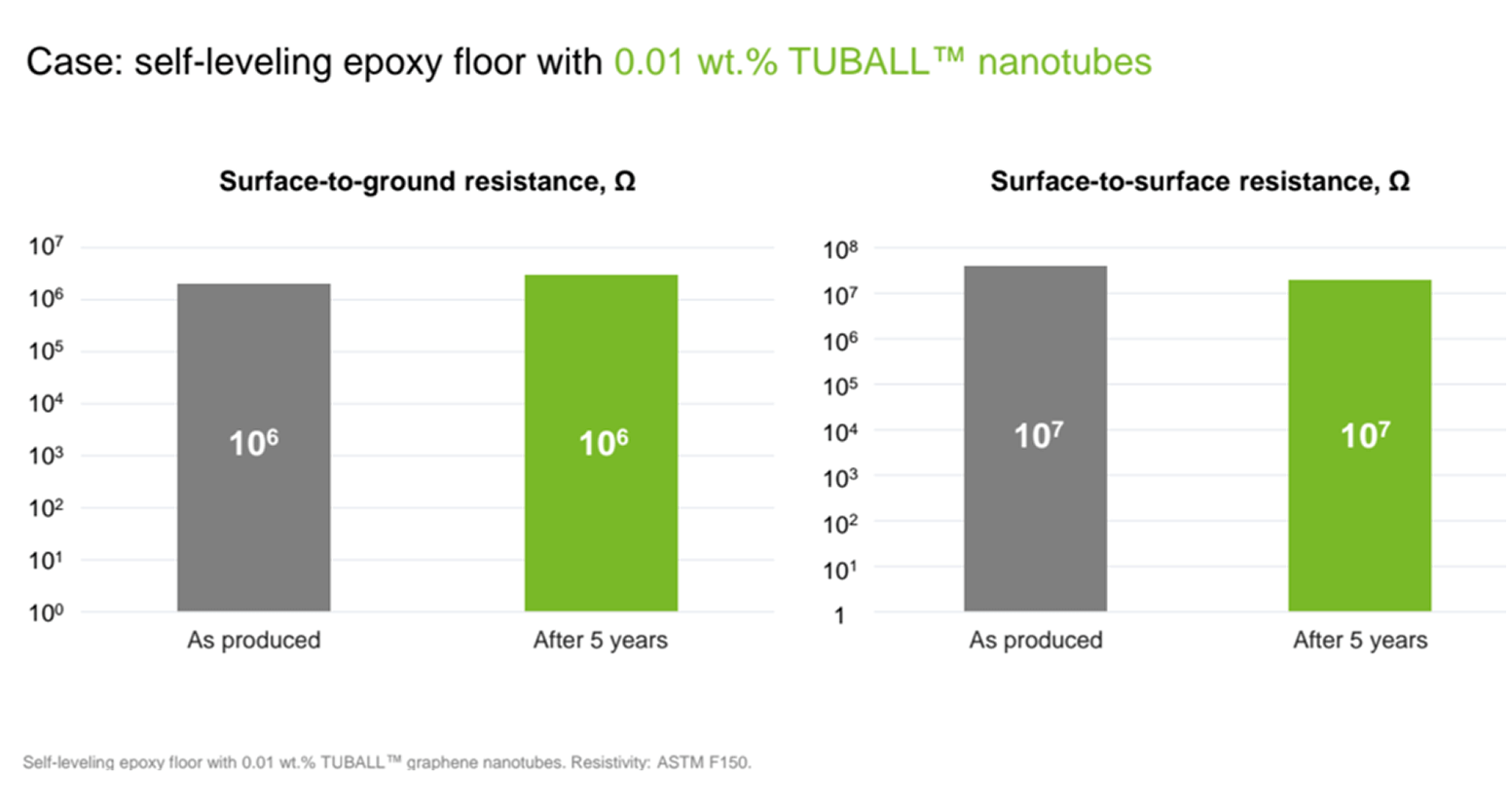

Permanent and stable resistivity over time

Added to resin, graphene nanotubes create a stable, permanent electrical pathway from the walking surface to the ground and dissipate electrostatic charge over time regardless of humidity.

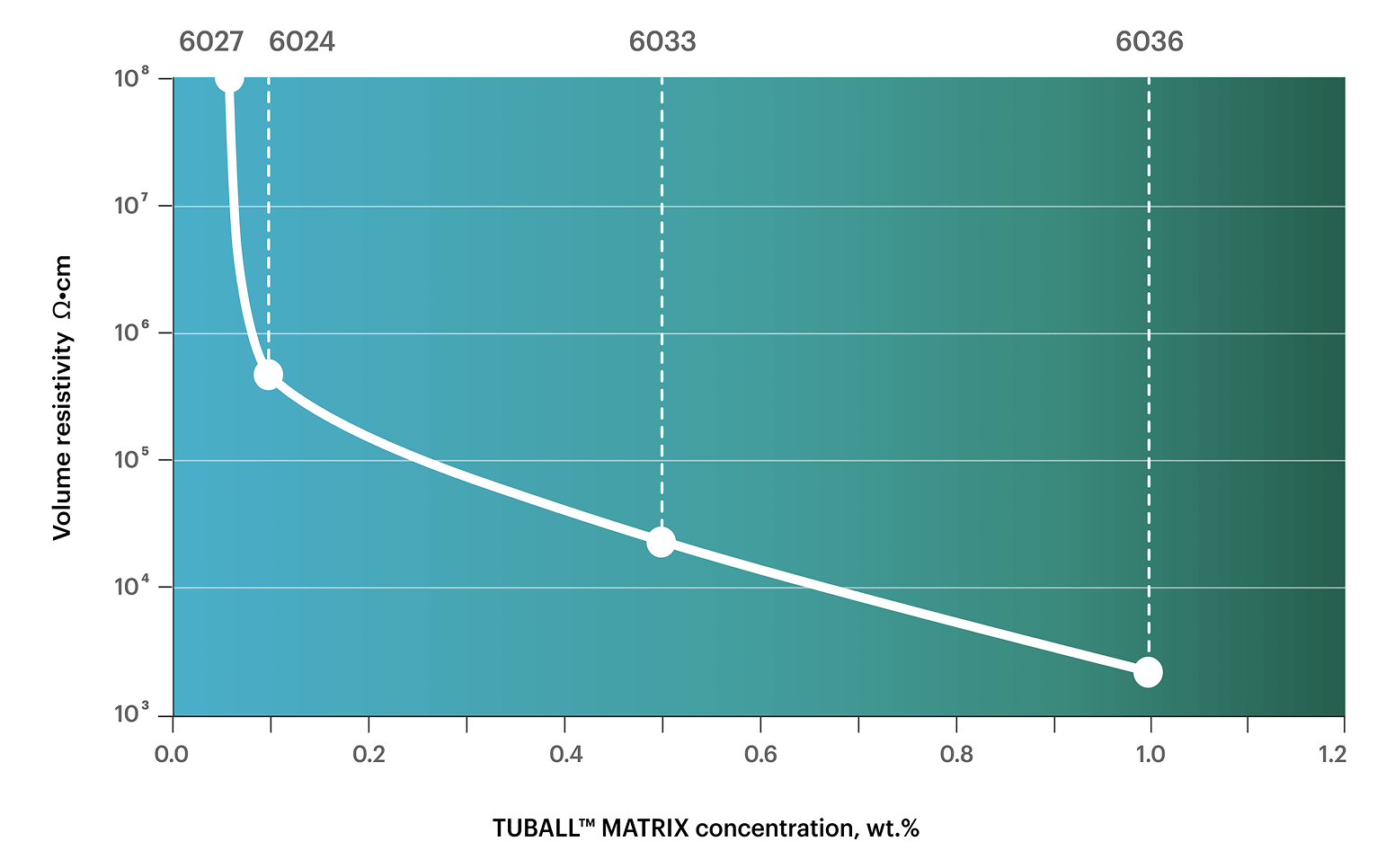

Full range of electrical resistivity while preserving color

Ultralow working dosages of graphene nanotubes allow for wide color flexibility while ensuring a wide range of stable electrical resistivity.

OCSiAl internal study. Thermoset-based systems.

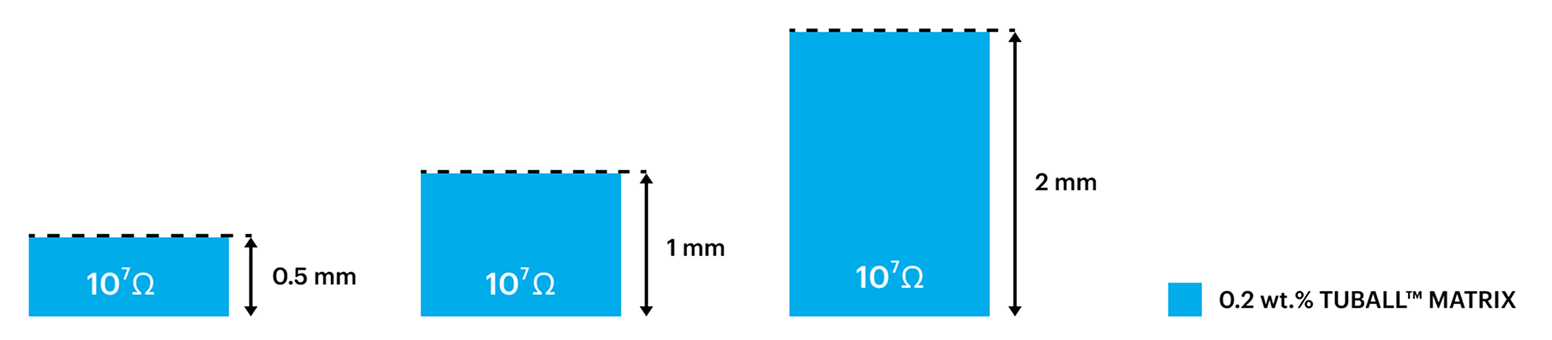

Low working dosages and flexibility in basecoat thickness

Compared with chopped carbon fiber and conductive mica, the required dosage of which is 5–20 wt.% leading to a higher price, graphene nanotubes make it possible to obtain the required conductivity at much lower working dosages starting from 0.01 wt.%, improving cost efficiency.

Surface-to-ground resistance at different base coat thicknesses

Due to the length of chopped carbon fiber (2 mm or longer), the base layer thickness must be at least ~2 mm, which complicates installation and raises costs. Additionally, the fiber’s morphology can potentially create insulating “hot spots.” In contrast, graphene nanotubes can be used with various anti-static flooring systems and thicknesses, ensuring stable, permanent surface-to-ground resistance, ultimately reducing ESD flooring costs.

APPLICATION_REQUEST_TITLE

Additional benefits

Make it possible to pass the walking body voltage test

Can be used without conductive primer*

Flexibility in final formulation

Limited influence on viscosity and thixotropy

Ensures ESD floor walking test compliance

Industry-friendly forms of nanotubes allow standard processing

TUBALL™ MATRIX 200-x and 300-x series is a line of additives based on polymer-carriers and pre-dispersed TUBALL™ graphene nanotubes. They are designed to provide compatibility with standard processes and equipment. The concentrates can be added during the latex or polyurethane compounding stage and don’t affect the manufacturing process.

TUBALL™ MATRIX

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX 200-x and 300-x

基于塑化剂(缩水甘油醚基)的导电和抗静电添加剂,用于无溶剂环氧涂料,颜色和机械性能方面无缺陷。

用于无溶剂环氧树脂和涂料的基于塑化剂(缩水甘油醚基)的导电添加剂,颜色和机械性能方面无缺陷。

用于无溶剂环氧复合材料、涂料和聚氨酯体系的导电添加剂,颜色和机械性能方面无缺陷。

用于无溶剂聚氨酯和酚醛体系的基于非邻苯二甲酸酯塑化剂的导电和抗静电添加剂,颜色和机械性能方面无缺陷。

用于需要溶剂的环氧树脂和聚氨酯涂料的基于塑化剂(缩水甘油醚基)的导电和抗静电添加剂,颜色和机械性能方面无缺陷。

用于需要溶剂的环氧树脂和聚氨酯涂料的基于塑化剂(缩水甘油醚基)的导电添加剂,颜色和机械性能方面无缺陷。

Application cases

Related video

3 reasons to choose graphene nanotubes for self-leveling anti-

Media on graphene nanotubes in floors

Overcoming ESD-Control Flooring Challenges: A Comprehensive Guide to ANSI/ESD S20.20-2021

https://www.floortrendsmag.com/articles/110984-overcoming-esd-control-flooring-challenges-a-comprehensive-guide-to-ansi-esd-s2020-2021

Exploring the Ability of Graphene Nanotubes to Enhance Coating Safety, Durability, and Performance

https://digitaledition.pcimag.com/september-2022/feature-ocsial/

Single Wall Carbon Nanotubes. Fundamental Improvement in ESD Flooring with 0.01% Additive.

https://www.coatingsworld.com/issues/2017-03-01/view_features/single-wall-carbon-nanotubes/Scientific validation

Raman Spectroscopy Unfolds the Fate and Transformation of SWCNTs after Abrasive Wear of Epoxy Floor Coatings

As a part of Diagonal EU project, FORTH, OCSiAl, STAT PEEL and other members examined TUBALL™ release from epoxy composites during abrasion tests. The level of nanotubes detected were below the LoQ.