Industrial

Coatings

Graphene nanotubes for coatings: conductivity, high performance, & aesthetics

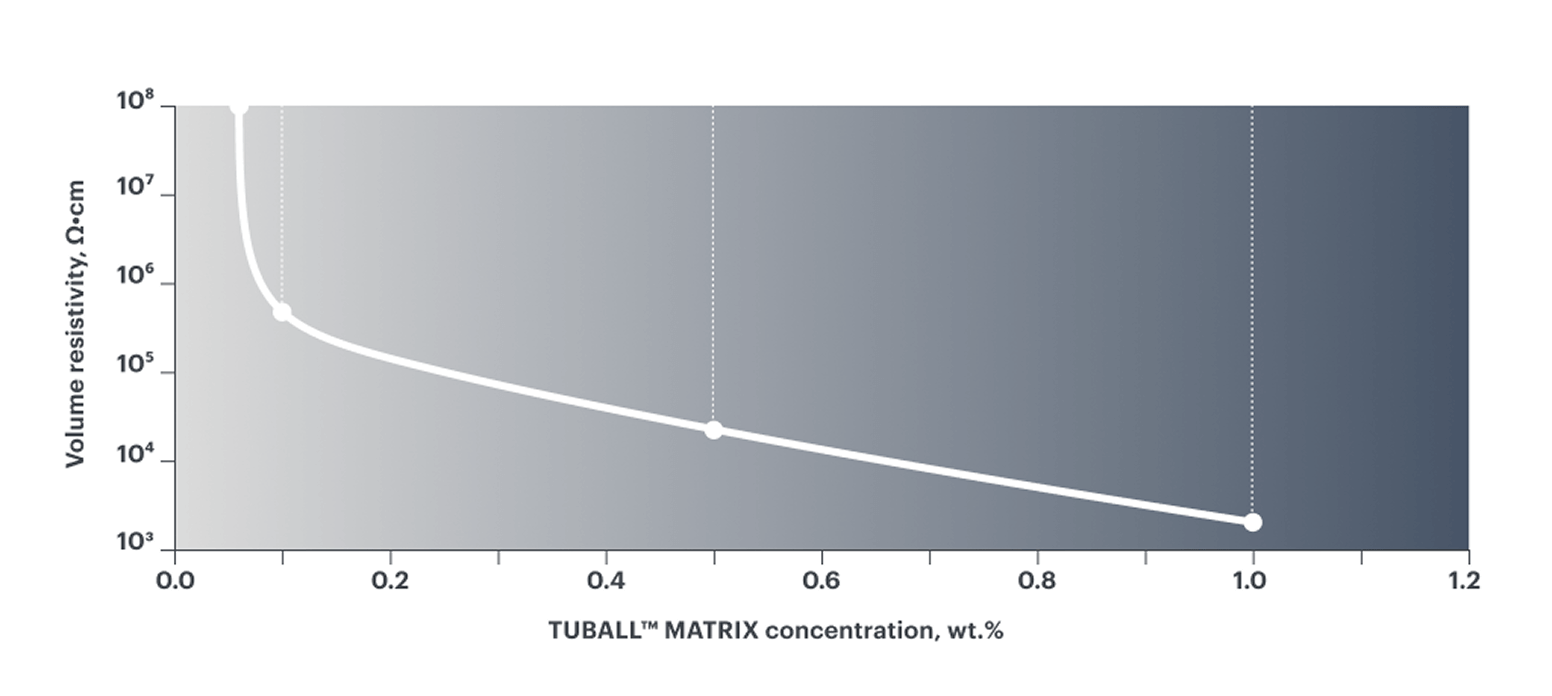

Graphene nanotubes allow manufacturers to create entirely new coatings with a full range of required properties, combining uniform, permanent electrical conductivity, maintained mechanical performance, and various colors. High-performance conductive coatings enhanced with nanotubes include anti-static lining coatings and gelcoats for electronic housings, conductive powder coatings and ESD flooring, electrically heated coatings, and tooling gelcoats. In contrast to standard anti-static additives, the working dosage of graphene nanotubes starts at just 0.01 wt.%. As a result, producers gain enhanced safety and prolonged durability of coatings while also contributing to lowering CO₂ emissions.

Main properties

Permanent

electrical resistance

10⁴–10¹¹ Ω

Preserved mechanical

properties

Colorful aesthetic

performance

Conductive industrial coatings for increased safety

What is the use of conductive coatings?

Conductive coatings are used to provide electrical conductivity to various surfaces, ensuring dissipation of static electricity and improved safety in electronic and industrial applications. They are essential in environments where static discharge could cause damage or ignite flammable materials, such as in electronics manufacturing and the automotive, aerospace, and other industries. Additionally, conductive coatings help to enhance the cost-efficiency of the manufacturing process by ensuring worker safety and decreasing the number of out-of-spec parts.

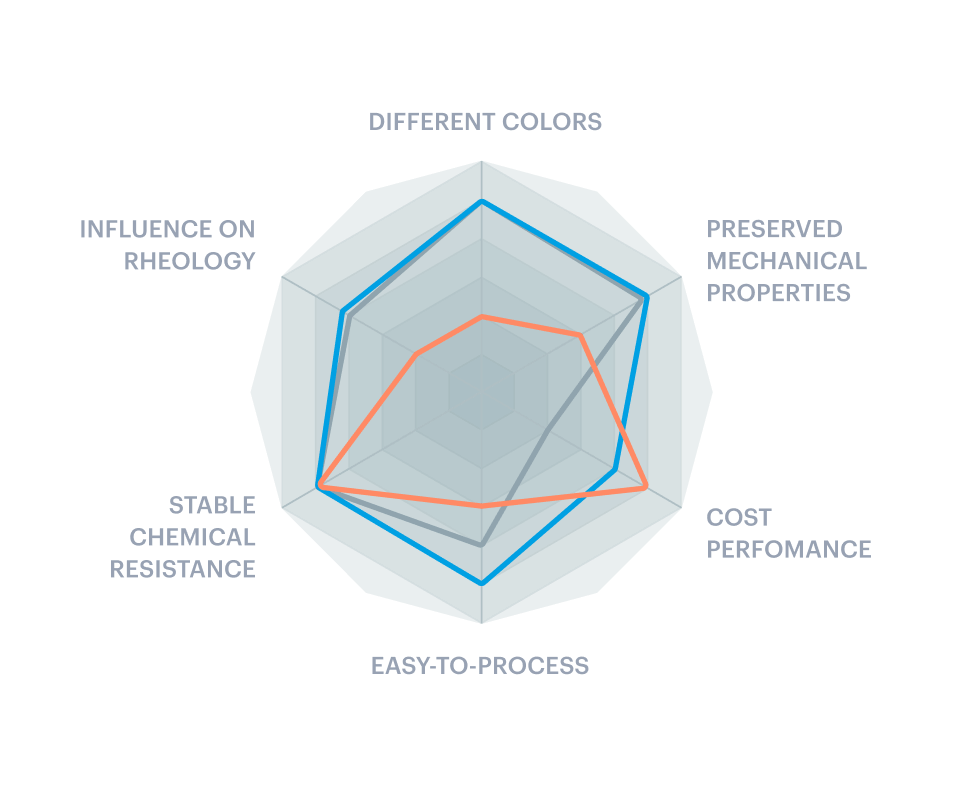

Graphene nanotubes outperform standard additives

Ultra-strong, electrically conductive, flexible graphene nanotubes form a 3D conductive and reinforcing network inside the material at ultralow dosages, opening the way for manufacturing higher performance, more durable coatings with various colors and less raw material required.

For example, for various thermoset-based (epoxy, polyurethane, polyester, acrylic, and others) coatings, TUBALL™ nanotubes make it possible to meet all key requirements, in contrast with standard conductive additives like carbon black, anti-static liquid agents, conductive mica, ammonium salts, etc.

- DIAGRAM

- TABLE

- TUBALL™

- Carbon black

- Conductive mica

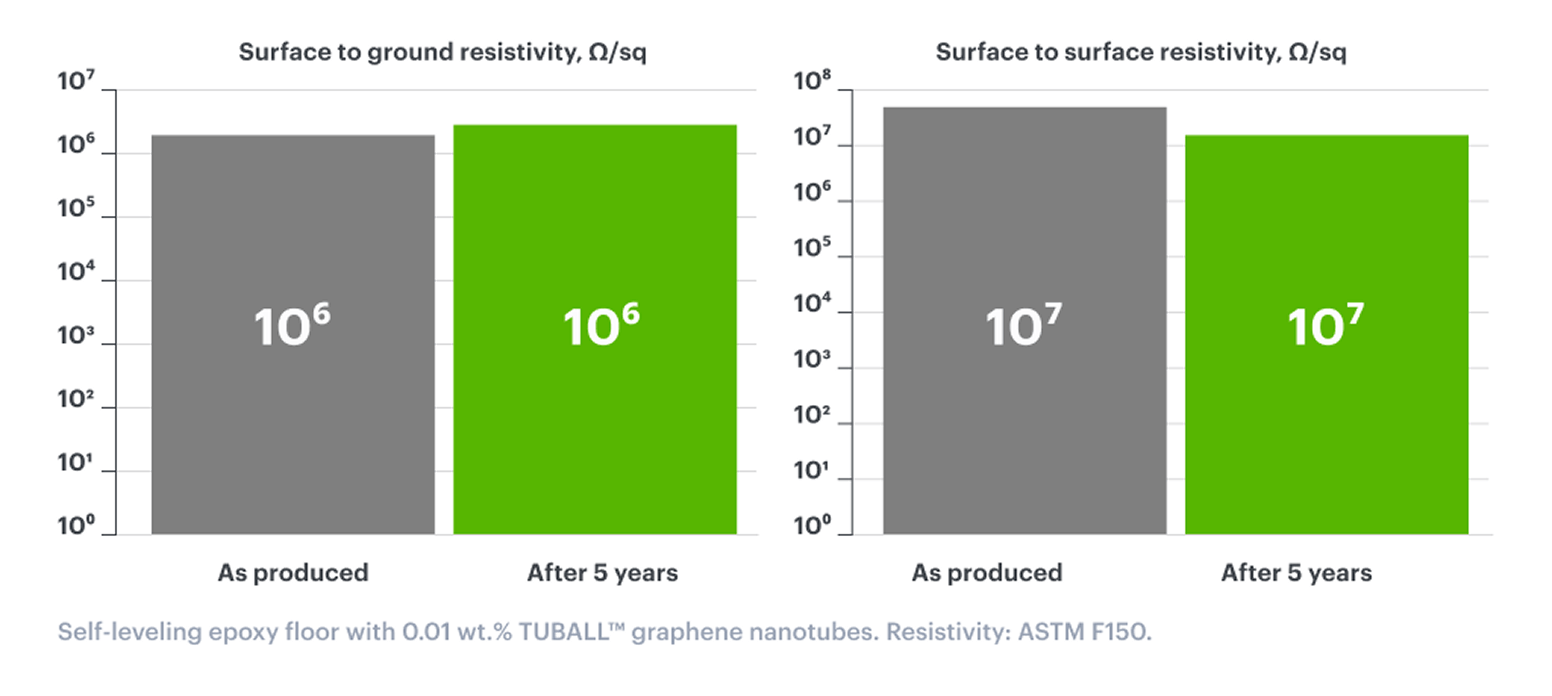

Permanent, stable conductivity

A distributed nanotube network inside the material guarantees permanent electrical conductivity without insulative spots and independent of humidity throughout its service life. Nanotubes’ unique morphology ensures no carbon release and prevents degradation of anti-static properties in various industrial coatings.

For example, self-leveling floors enhanced with TUBALL™ nanotubes maintain their electrically conductive properties over many years without degradation.

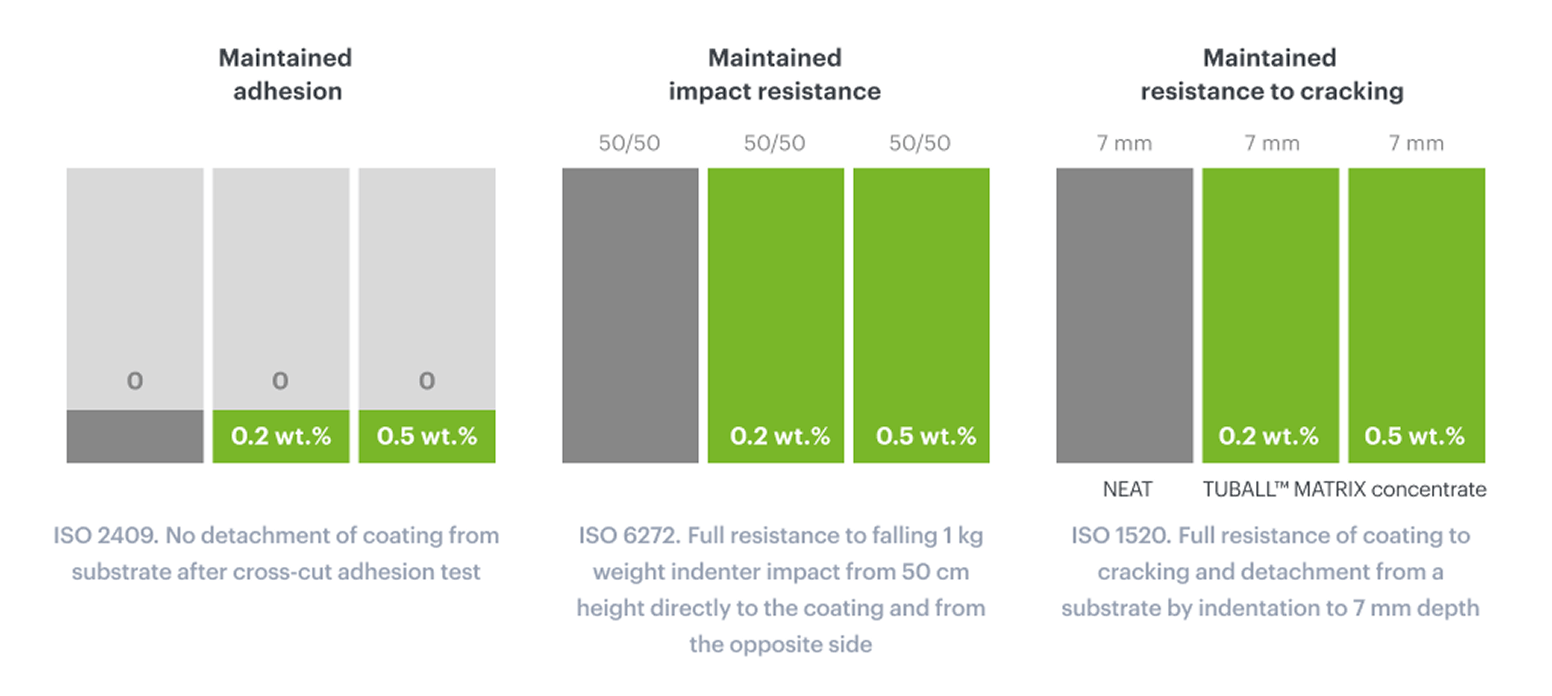

Maintained mechanical performance

The ultralow working dosage of graphene nanotubes, starting from 0.02 wt.%, and their unique morphology makes it possible to retain or even improve key mechanical properties of coatings, including adhesion, impact resistance, crack resistance, and chemical resistance.

For powder coatings, TUBALL™ nanotubes ensure a full range of resistivity, preserve mechanical properties, while requiring no change in standard production processes.

Preserved variety of colors

Having a high aspect ratio and forming a spatial conductive network at very low loading rates, graphene nanotubes provide greater control over color and finish. This makes it possible to avoid dark shades in the final coating and meet customer requirements, including facilitating visual inspections and more efficient servicing.

For lining coatings, TUBALL™ nanotubes provide electrical conductivity while allowing light colors to facilitate visual inspections of tank coatings.

APPLICATION_REQUEST_TITLE

Additional benefits

Limited influence on rheology

Flexibility in formulation

More efficient logistics

Standard processing

TUBALL™ graphene nanotubes are available in industry-friendly forms of concentrates and suspensions that guarantee clean production and the ability to use standard industrial equipment. They were specifically designed for various coating systems, including solvent-free or solvent-based epoxy, polyurethane, polyester, vinyl-ester, melamine, and acrylic. Concentrates and suspensions can be added during the compounding stage and don’t affect the manufacturing process.

TUBALL™ BATT H2O是 TUBALL™单壁碳纳米管在水中的超细分散液,用于高能量硅负极。单壁碳纳米管在硅负极中形成强韧的网络,解决负极劣化,首次使锂离子电池生产商能够在电池中使用破纪录的硅量并达到理想的能量密度,并同时实现快速充电的功能。

Application cases

Related video

How can you prevent ESD damage to your workers and equipment?

Media on graphene nanotubes in industrial coatings

Expanding the freedom of design: powder coating on FRP thanks to conductive gelcoats with graphene nanotubes

https://www.nanotech-now.com/news.cgi?story_id=56585

Graphene nanotubes provide a shortcut to add conductivity to powder coatings

http://www.ultraglasscoatings.co.uk/nanotechnology-now-press-release-graphene-nanotubes-provide-a-shortcut-to-add-conductivity-to-powder-coatings/

Graphene nanotubes offer an efficient replacement for carbon additives in conductive electrical heating paints

https://statnano.com/world-news/88575/Nanotechnology-Now-Press-Release-Graphene-nanotubes-offer-an-efficient-replacement-for-carbon-additives-in-conductive-electrical-heating-paints#ixzz8sfKqHxG4

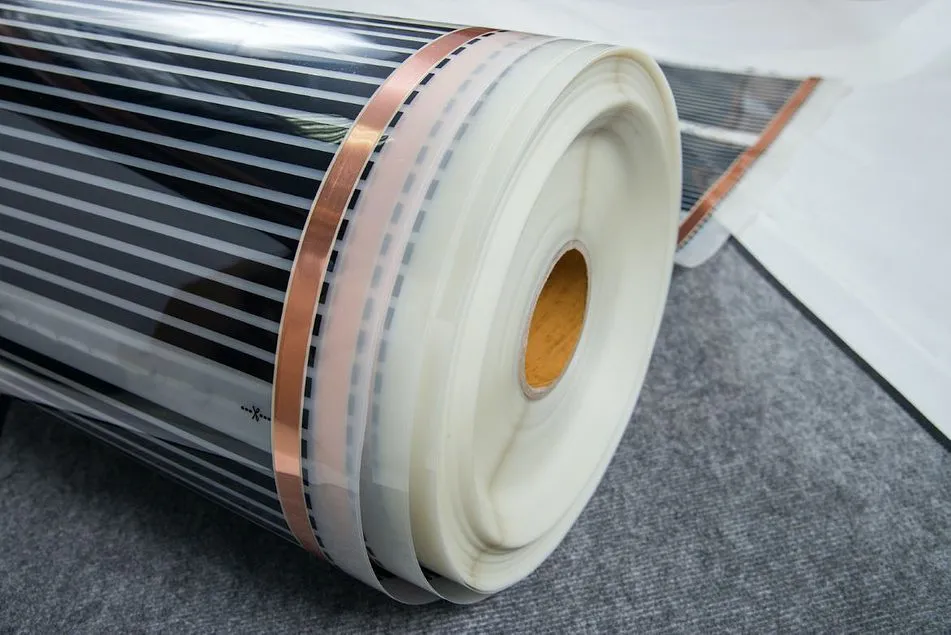

Heating Films with Graphene Nanotubes Enter the Market

https://www.pcimag.com/articles/109495-heating-films-with-graphene-nanotubes-enter-the-marketScientific validation

Raman Spectroscopy Unfolds the Fate and Transformation of SWCNTs after Abrasive Wear of Epoxy Floor Coatings

As a part of Diagonal EU project, FORTH, OCSiAl, STAT PEEL and other members examined TUBALL™ release from epoxy composites during abrasion tests. The level of nanotubes detected were below the LoQ.

Enhancing the Electrical Conductivity and Strength of PET by Single-Wall Carbon Nanotube Film Coating

TUBALL™ SWCNTs were hot-pressed onto PET films, forming a uniform, conductive network that significantly boosted electrical and mechanical performance at an ultralow loading of just 0.066 wt%. The resulting SWCNT/PET hybrid film achieved low surface resistance, with notable gains in tensile strength and modulus, offering durable, thermally stable performance for antistatic applications.