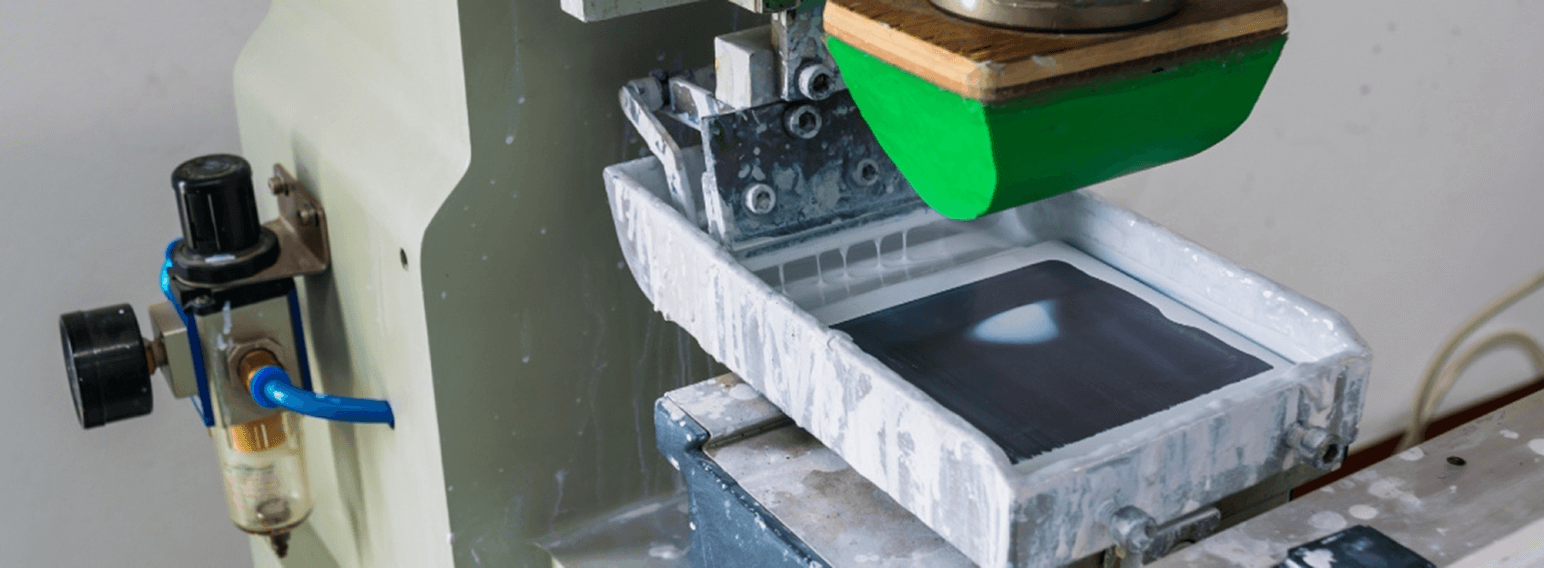

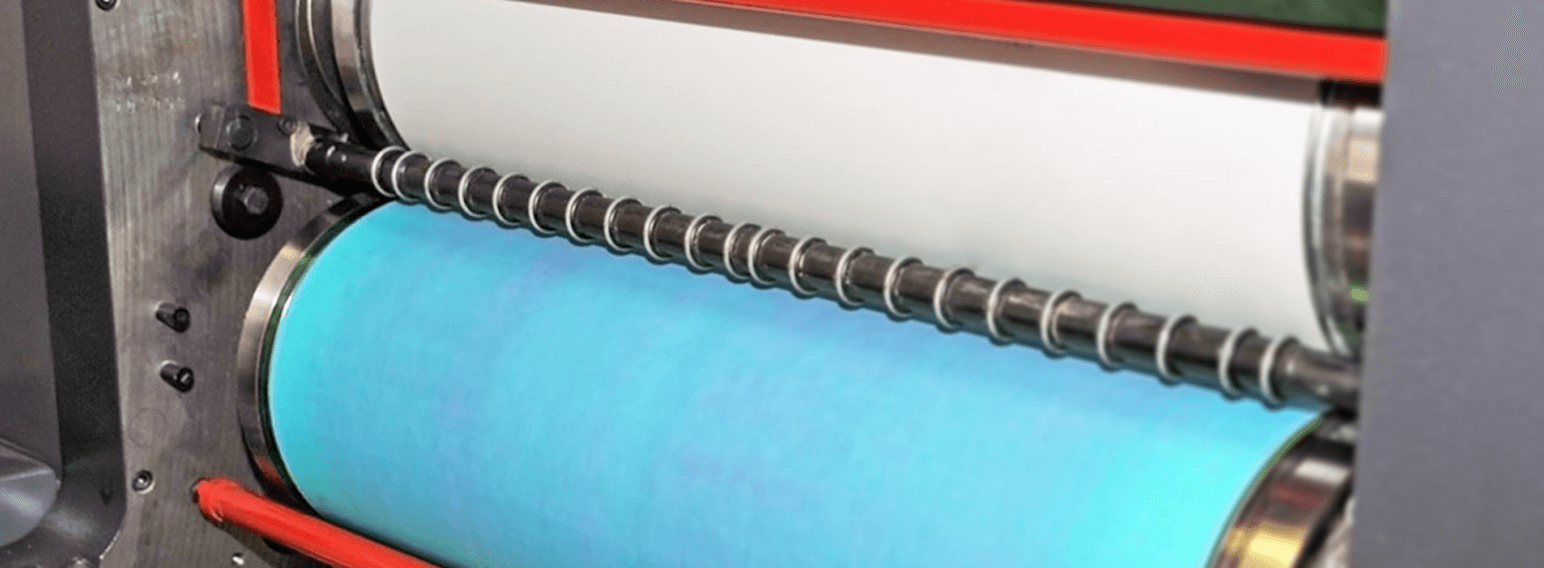

Rollers and sleeves

Graphene nanotubes in rubber, polyurethane, or fiberglass composite printing sleeves and rollers form a permanent conductive network for ESD-safe, low-defect printing. With no carbon migration, the rollers maintain their strong mechanical performance, clean surfaces, and coloring possibility. Their durable, conductive design works with all major ink types and ensures stable, non-marking performance in flexographic printing on plastic, cardboard, and paper.