Lining

coatings

Graphene nanotubes for tank lining coatings: electrical conductivity, durability, and light colors

TUBALL™ graphene nanotubes enhance tank coatings by providing stable, uniform electrical conductivity while preserving the original mechanical properties of the material. Nanotubes enable the creation of light-colored, durable coatings with ESD protection using standard production technology and equipment.

Graphene nanotube-enhanced anti-static lining coatings comply with international standards and recommendations, including EN 14015, TRbF 401, NFPA 77, and other regional versions. By installing these coatings, manufacturers can overcome the limitations of conventional conductive agents, while end-users can simplify tank visual inspections and regular maintenance.

Main properties

Surface resistivity

<10⁴–10⁹ Ω/sq

Variety

of colors

Maintained mechanical

properties

Conductive tank linings

What is a conductive lining coating?

Conductive lining coatings are specialized protective layers designed to prevent static charge buildup inside storage tanks and containers. By incorporating conductive materials, these coatings ensure safe electrostatic dissipation (ESD), reducing the risk of sparks and explosions when handling flammable liquids or powders.

They are widely used in industries such as chemicals, oil and gas, and pharmaceuticals where safe storage and transportation of hazardous materials are critical. These coatings help comply with safety standards and improve maintenance efficiency while preserving the integrity of the stored materials.

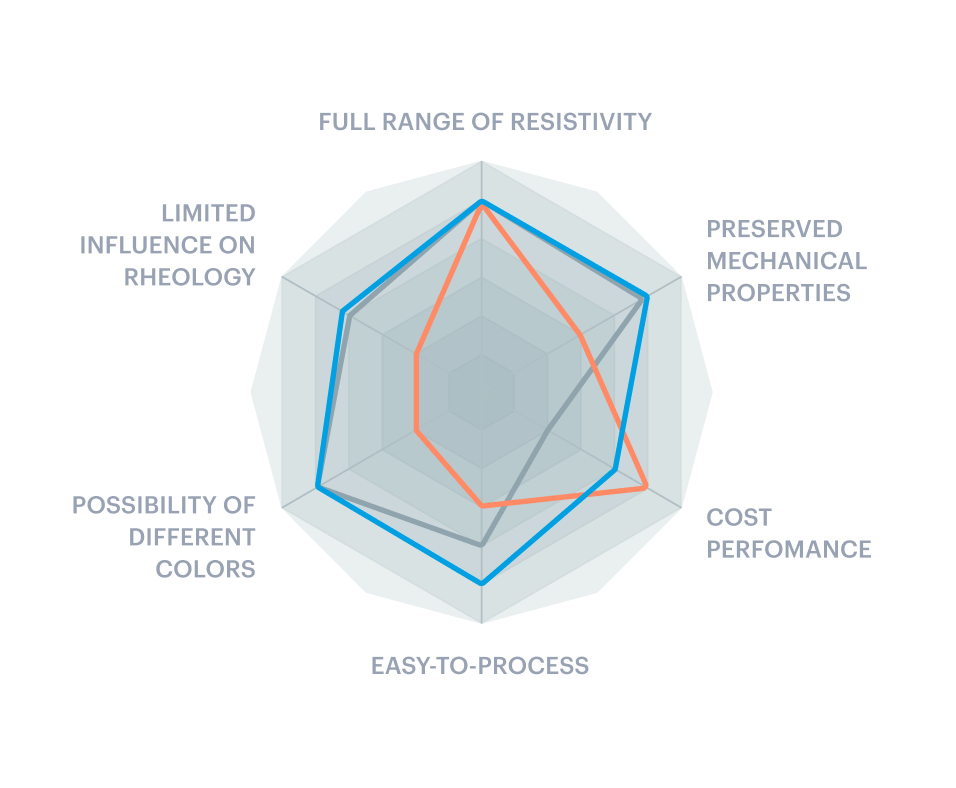

Graphene nanotubes outperform standard additives

TUBALL™ graphene nanotubes provide stable electrical conductivity in tank lining coatings, offering a superior alternative to graphite powder and conductive mica. These ultra-strong, electrically conductive, flexible nanotubes are effective at ultralow dosages—dozens of times lower than conventional additives—delivering unmatched performance. The result is electrostatic dissipative, durable, high-performance coatings with maintained mechanical properties and required lighter colors.

- DIAGRAM

- TABLE

- TUBALL™

- Carbon black

- Conductive mica

Permanent, stable conductivity

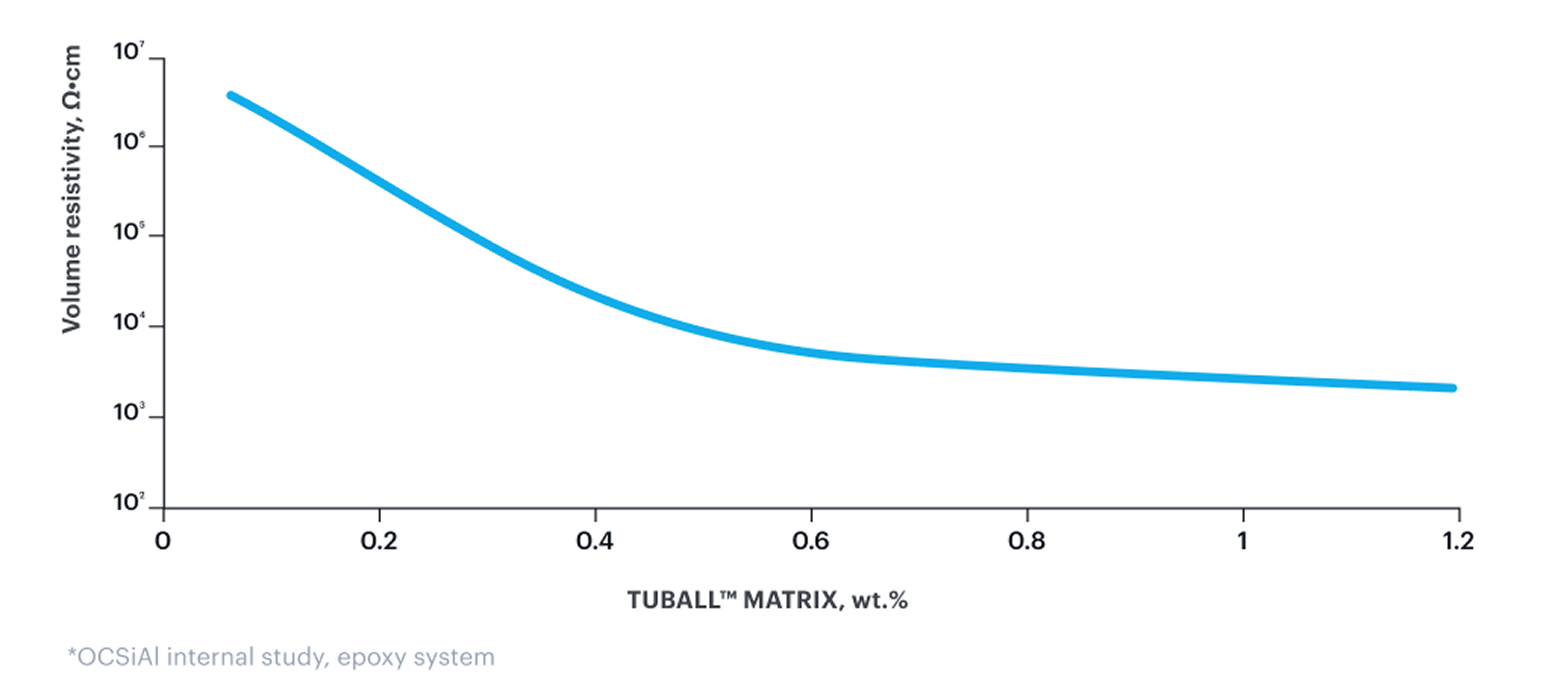

TUBALL™ graphene nanotubes in epoxy coatings provide stable, permanent surface resistivity of 10⁴–10⁹ ohm/sq that remains consistent over time and is independent of humidity, with no insulating spots.

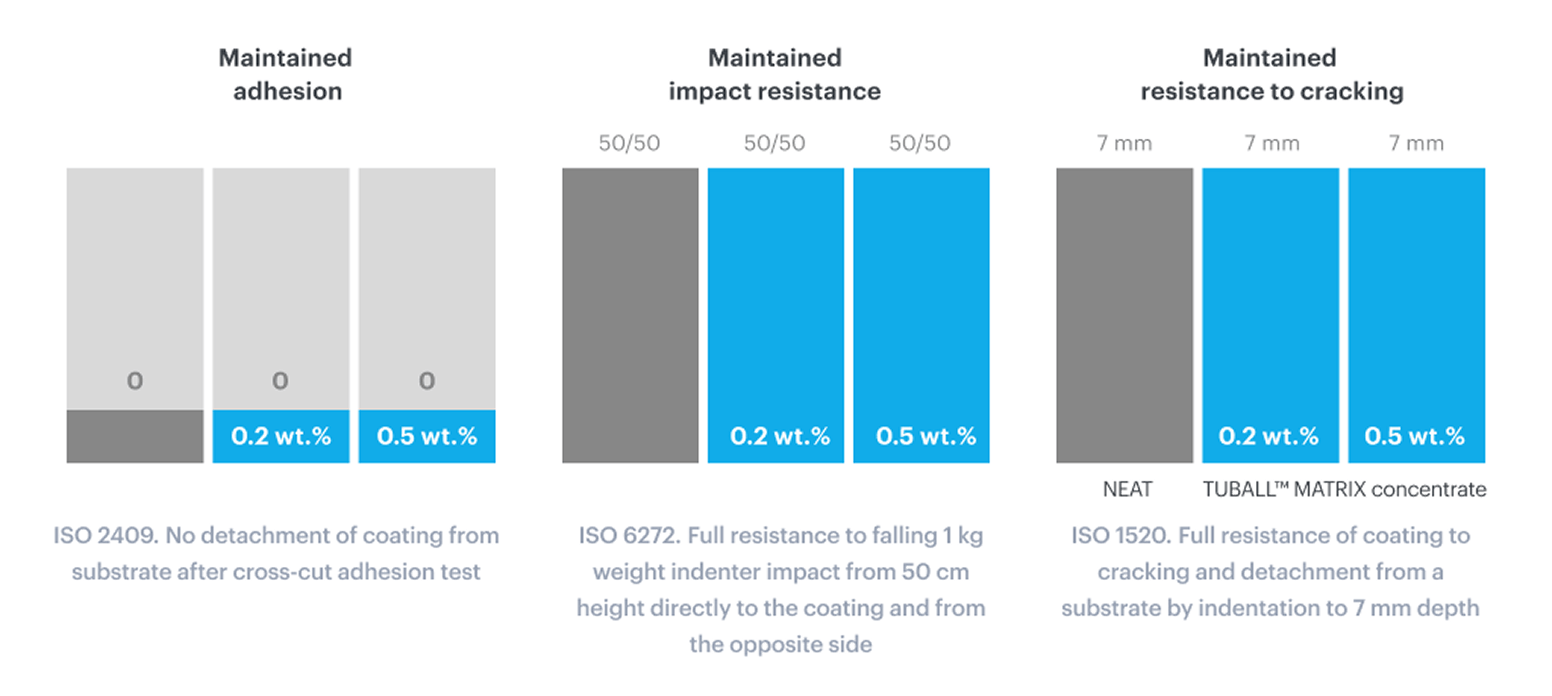

Maintained mechanical properties

In contrast to conventional conductive additives, TUBALL™ nanotubes unique morphology and the ultralow dosage required help preserve high bond strength and adhesion, as well as resistance to wear, abrasion, and impact. This makes it possible to avoid time-consuming and costly remedial maintenance.

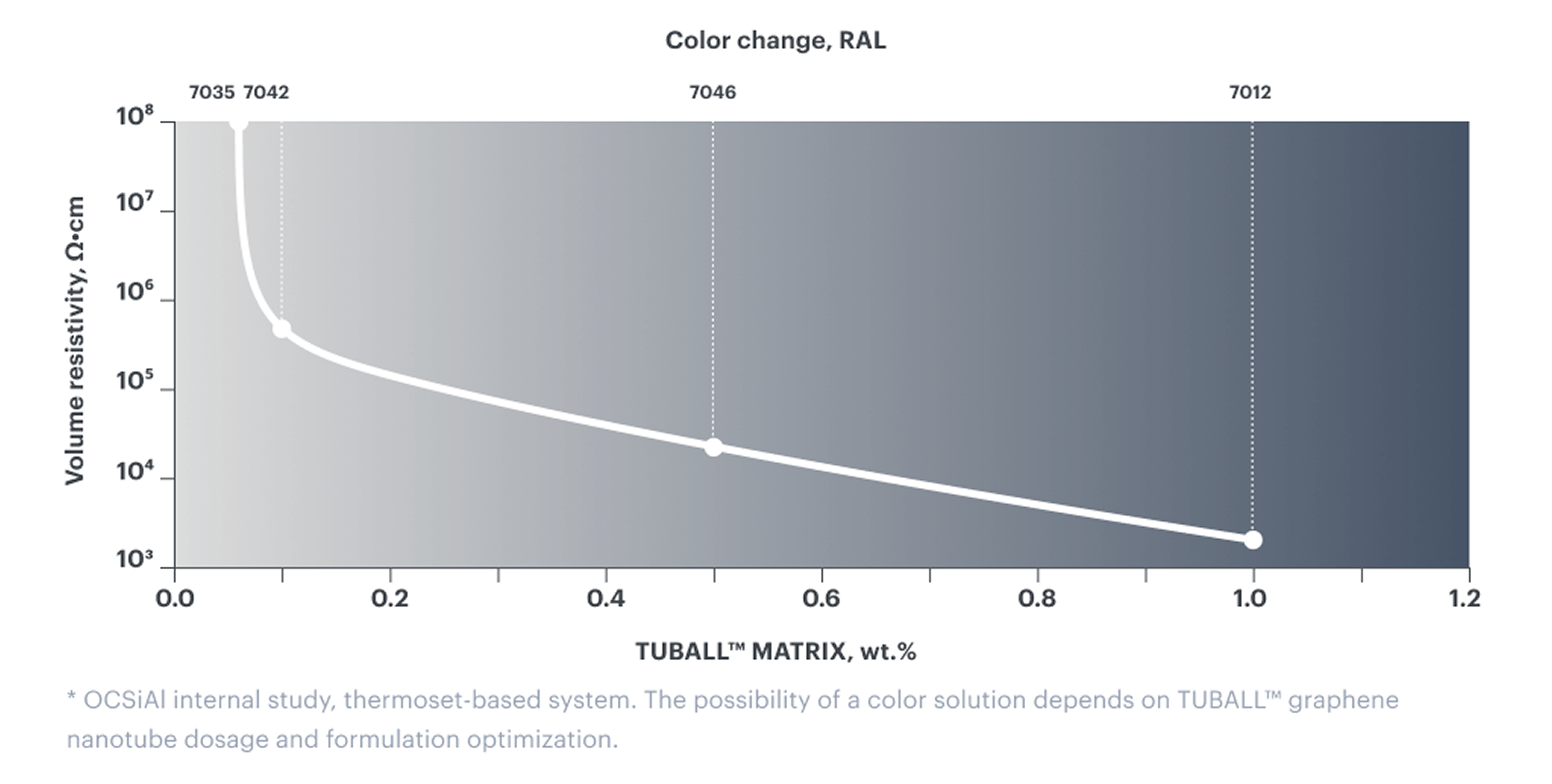

Light-colored coatings

The tiny amount—just 0.1 wt.%—of 10% TUBALL™ nanotube concentrate required to achieve permanent electrical conductivity in lining coatings allows light colors to be preserved. A wide range of available colors accelerates visual inspections and improves servicing efficiency. This also enables a servicing company to apply a light-colored top layer. Any contrast between top and base layers indicates insufficient coating thickness, making it easy to identify areas that need maintenance. Additionally, during operation, a light-colored lining makes it much easier to inspect for defects on the internal surface.

APPLICATION_REQUEST_TITLE

Additional benefits

Maintained chemical resistance

Less influence on rheology

Flexibility of formulation

Industry-friendly forms of nanotubes for standard processing

TUBALL™ graphene nanotubes are available in the industry-friendly form of concentrates that guarantee clean production and the ability to use standard industrial equipment. Depending on the specific polyurethane system and presence of solvent, one of the following concentrates should be selected: TUBALL™ MATRIX 201, TUBALL™ MATRIX 203, TUBALL™ MATRIX 207, TUBALL™ MATRIX 208, or TUBALL™ MATRIX 301. Concentrates can be added during the compounding stage and don’t affect the manufacturing process.

基于塑化剂(缩水甘油醚基)的导电和抗静电添加剂,用于无溶剂环氧涂料,颜色和机械性能方面无缺陷。

用于无溶剂环氧树脂和涂料的基于塑化剂(缩水甘油醚基)的导电添加剂,颜色和机械性能方面无缺陷。

用于需要溶剂的环氧树脂和聚氨酯涂料的基于塑化剂(缩水甘油醚基)的导电添加剂,颜色和机械性能方面无缺陷。

用于无溶剂环氧复合材料、涂料和聚氨酯体系的导电添加剂,颜色和机械性能方面无缺陷。

Application cases

Related video

Electroconductive lining and epoxy coatings - Project-based solutions