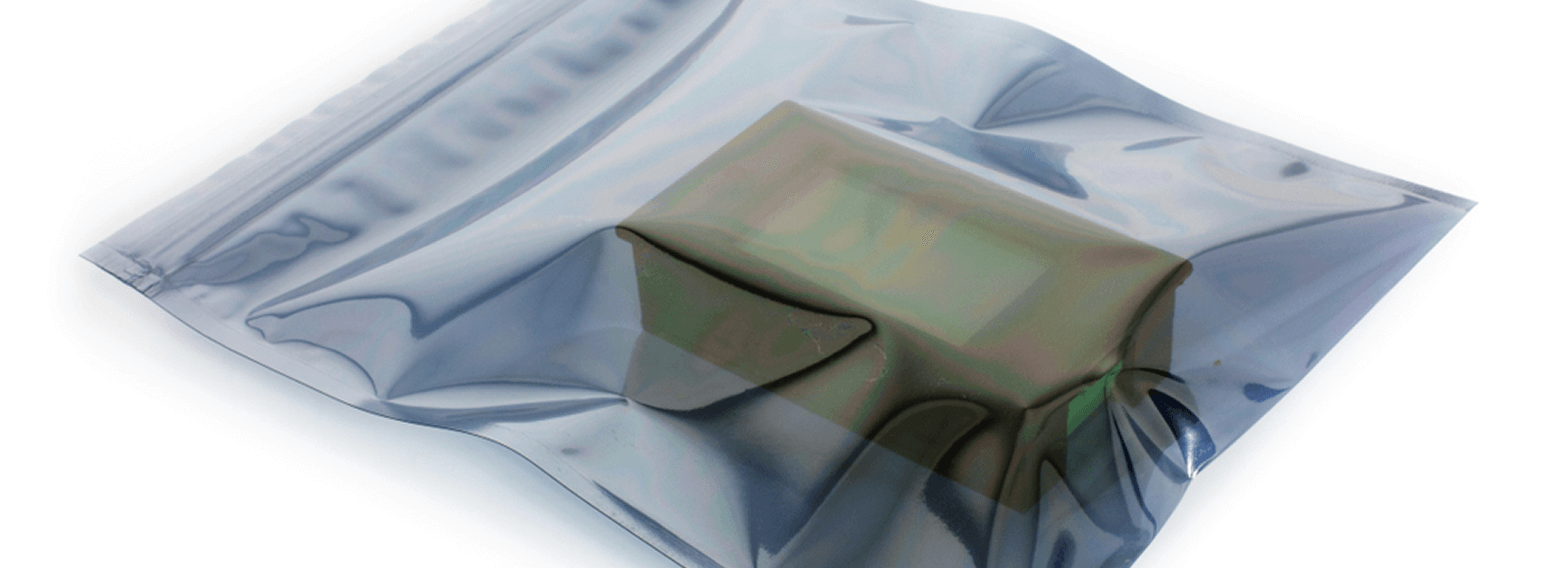

Industrial storage

Graphene nanotube–enhanced rotomolded polyethylene containers and GFRP tanks provide permanent, stable anti-static performance for the safe storage of flammable chemicals, unaffected by humidity or time. They also preserve high mechanical strength and color flexibility, allowing the creation of durable and customizable storage solutions.